Nowadays, consumers in many parts of the world hope their wooden flooring, decorations, and cabinets look and feel natural, requiring a smooth, transparent, and low gloss coating to protect the wood. In addition, water-based wood coatings with easier cleaning and lower volatile organic carbon (VOC) content are also needed. However, these wood coatings must also have excellent mechanical and chemical resistance to be durable enough to give the resulting wood products a sufficient lifespan. Low VOC water-based wood coatings are still more prone to wear, scratches, and damage than solvent-based wood coatings using harder resins.

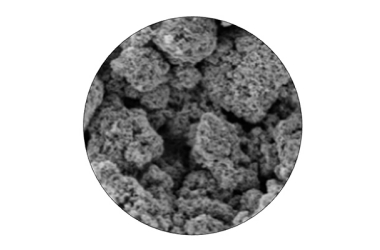

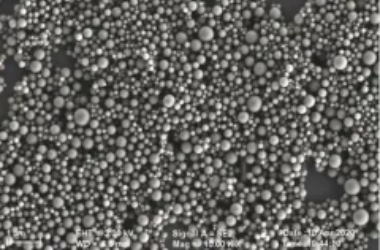

Wax-based matting agents can achieve semi-matte gloss levels with a considerable degree of polishing and scratch resistance. In contrast, natural and organic polymer fillers can achieve lower glossiness. However, deep matte wood finishes (60 ° glossiness less than 5 GU, 85 ° glossiness much lower than 20 GU) typically require coatings containing silica-based matting agents. Due to their manufacturing process, silicon dioxide-based extinction agents have rough, irregular surfaces and a considerable degree of porosity. Used for producing spherical precipitated silica and alkali aluminosilicates, these processes have been proven useful as abrasive cleaners in dental cleanser compositions. This new process, in which the acidifier and alkali metal silicate are straight fed into a circular reaction zone containing a liquid reaction medium flow, can be operated under various reaction conditions to generate spherical silica particles with unique properties. In addition, spherical precipitated silica particles with extremely low surface area, low oil absorption rate, and extremely narrow particle size distribution can also be produced.

Spherical silica powder is a new type of material.

The characteristics of spherical silica powder:

- Excellent dielectric performance: Its dielectric performance is very stable at various frequencies and temperatures.

- Low coefficient of thermal expansion: This allows it to maintain stability in different temperature environments, reducing deformation caused by temperature changes.

- Good electrical insulation: suitable for situations that require high insulation performance.

- Forming multiple layers of protective layer during oxidation enhances its ability to resist oxidation and corrosion.

- It has good mechanical properties and high-temperature oxidation resistance, allowing it to perform well even in high temperatures and harsh environments.

Application of spherical silica powder:

- Due to its excellent dielectric properties, coefficient of thermal expansion, electrical insulation, and high-temperature oxidation resistance, it is widely used in the manufacturing of quartz ceramics. After adding spherical silicon micro powder, quartz ceramics become denser, heat-resistant, and cold-fatigued, greatly improving their strength.

- The quartz ceramic crucible used for polycrystalline silicon ingots can greatly improve the strength and yield of the crucible and reduce demolding time.

Supplier

TRUNNANO is a supplier of molybdenum disulfide with over 12 years of experience in the manufacturing of chemical materials. It accepts payments through credit cards, T/T, Western Union transfers, and PayPal. Trunnano will ship the goods to overseas clients through FedEx, DHL, and air or sea freight. If you are pursuing high-quality spherical silica powder, please get in touch with us and inquire.